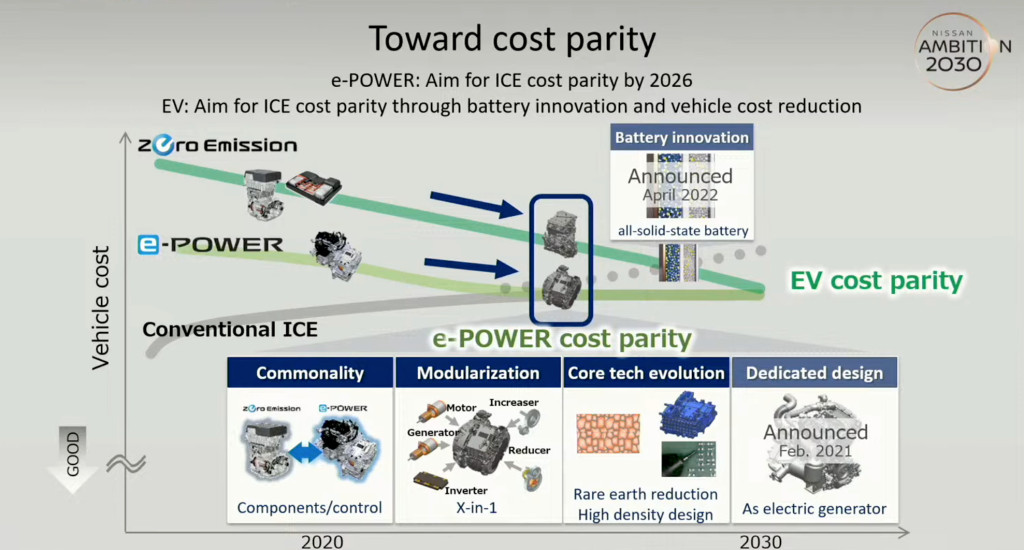

Nissan on Wednesday revealed a new approach to developing the core components for its EV and e-Power series hybrid models—leading to what Nissan believes to be price parity with non-hybrid internal combustion models around 2026.

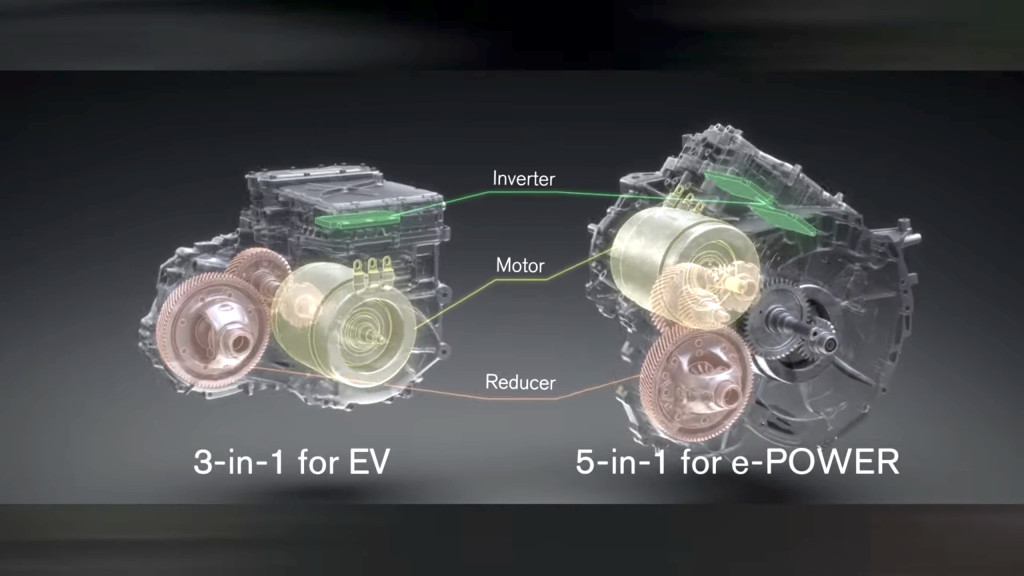

Under the so-called X-in-1 philosophy, core components of both battery electric and e-Power powertrains (3 for EV, 5 for e-Power) will be modularized, with some sharing between the two—an approach that allows them to be produced on the same line.

Such sharing and modularization of core components will help reduce powertrain costs by approximately 30% when it’s introduced in 2024, compared to 2019, and by around 2026, when they are due to be ramped up for mass production, it will enable that price parity.

Nissan E-Power shares tech between EVs and hybrids

Nissan’s e-Power models are series hybrids—meaning that a gasoline engine drives a generator, while an electric motor drives the wheels (with a modest battery buffer in the middle). Nissan hasn’t ruled out the idea of plug-in hybrids, but all of its e-Power models as of yet have stuck to the gasoline-fueled format.

E-Power made its debut in 2016 on the Japan-market Note small car, and since then it’s pushed the system out to more models and made the Note all-hybrid, with the tech now arriving in Europe.

Nissan X-in-1 approach to modularize EV and e-Power components

Nissan X-in-1 approach to modularize EV and e-Power components

Nissan X-in-1 approach to modularize EV and e-Power components

The more focused sharing of motor and inverter technology between e-Power and its EVs will help lower the costs of both, and Nissan noted it’s heading into its third generation of in-house inverters, with significant progress in efficiency and downsizing. It’s also adding a newly developed motor that reduces the use of heavy rare earth elements to 1% or less of the magnets’ weight, Nissan says, while the modularization itself will reduce size by 10% and help control noise and vibration.

In a little more detail, the EV version combines the motor, inverter, and reduction gear, while the e-Power version combines the motor, inverter, generator, reduction gear, and engine-generator gear. Nissan’s affiliated transmission supplier Jatco will package the components together in modules.

Nissan e-Power hybrids for North America?

Nissan didn’t discuss applications for North America in a virtual reveal of the tech or in an accompanying press release. But according to Automotive News, citing senior vice president Toshihiro Hirai, e-Power may be used in future body-on-frame vehicles.

That could refer to a wide range of potential vehicles, including fleet delivery vans, other commercial vehicles, or personal-use pickups or SUVs—or all of the above.

2022 Nissan Qashqai E-Power

In the U.S. Nissan has sent many mixed messages about e-Power hybrids—and how its North American EV lineup might look later in the decade. But this announcement could be a positive step for the rollout of these technologies.

The parent company originally said that it intended to roll out a version of it as a mass-market hybrid system for North America, replacing its limited-availability Rogue Hybrid and perhaps eventually taking on the hybrid-rich product mix of the Toyota RAV4 or Ford Escape. In 2019, it instead said that while it was still studying the tech for America, e-Power hybrids for the U.S. would aim for performance rather than just fuel economy.

Later in 2019, its Infiniti luxury brand revealed a sweeping plan to refocus its lineup around EVs and a version of e-Power, but by mid 2021 it dropped that high-tech vision.

Nissan seeking cost parity with EVs, e-Power hybrids

EV price war? The modular approach might help

Nissan has hinted at a replacement for its Leaf, due around 2026, and the possibility of an electric compact truck. Both would be cost-conscious product aided by this modular approach.

Looking at what Nissan has confirmed: Mid-decade in Mississippi, it plans to ramp up the production of two new EVs—one for the Nissan brand, the other for Infiniti.

Nissan EV to be made in Mississippi

Nissan USA told Green Car Reports that it could neither verify the modular system for those nor provide any update on the timeline for e-Power in the U.S.

Looking solely at EVs, Nissan sees cost parity as further out—and it again pointed to its anticipated introduction of its own solid-state batteries around 2028, with mass-market scale a couple years later, as a key to that.