Volvo is revamping its largest factory to produce next-generation electric cars more efficiently.

The roughly $1 billion investment in Volvo's Torslanda, Sweden, plant includes a new battery assembly facility, fully refurbished paint and final assembly shops, and the introduction of a "mega casting" method for aluminum parts, Volvo said Tuesday in a press release.

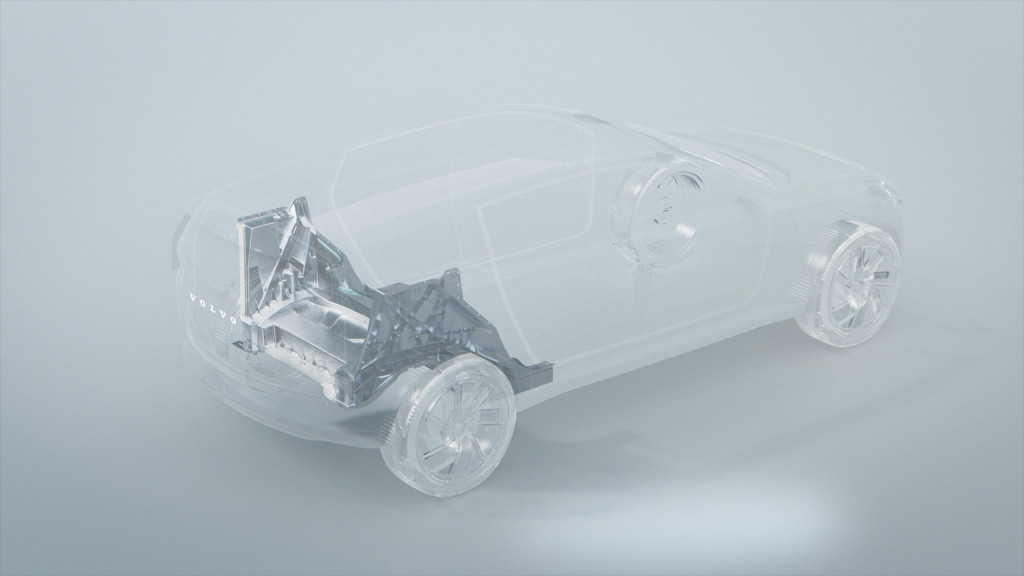

Mega casting refers to the use of large single aluminum castings for major components, such as the floor structure. This reduces weight (helping to improve range and efficiency) and also allows designers to make better use of interior space, according to Volvo. Another benefit of mega casting will be reduced manufacturing complexity, which will lead to cost savings and a lower environmental impact, Volvo claims.

Volvo mega casting

It also sounds like a process similar to what Tesla is ramping up at its Texas factory, first on the Model Y. It's a process that's been mentioned repeatedly by Tesla CEO Elon Musk as important for future profitability and scaling up—and that it could produce more consistent vehicles.

Volvo also plans to upgrade the Torslanda plant's paint shop with new machinery and painting processes, which the automaker claims will reduce energy use and emissions.

The new battery assembly plant will place cells into modules and packs, while the assembly shop will be modified to accommodate EV-specific processes, such as marrying the battery pack to the vehicle structure, Volvo said. The plant's logistics area will also get upgrades to optimize the flow of parts, the automaker said.

Volvo mega casting

Opened in 1964, the Torslanda plant currently has an annual production capacity of 300,000 cars, according to Volvo. That makes it the automaker's largest plant, and it was once the largest single workplace in Sweden, Volvo claims.

The focus on addressing manufacturing-related emissions while upgrading the plant for EVs fits with Volvo's effort to track the CO2 footprint of its own vehicles, from manufacturing through end of use. Volvo also plans to go leather-free to further lower its environmental impact.

Just last week Volvo also revealed plans for a mammoth, joint-venture battery plant with Northvolt near Gothenburg, Sweden. Scheduled to open in 2025, it will have a "potential" annual cell production capacity for 500,000 EVs, Volvo claims.