Ford and the battery supplier SK Innovation on Thursday announced a joint venture, called BlueOvalSK, that will manufacture battery cells and arrays in the U.S. for future electric vehicles.

The joint venture will produce 60 gigawatt-hours of cells annually by the middle of the decade, the companies said, with the potential to expand the business later.

SK Innovation has already started producing cells in Georgia and is due to supply them for the 2022 Ford F-150 Lightning electric pickup revealed Wednesday and set to arrive next year.

Artist's rendering of SK Innovation battery factories in Commerce, Georgia

The F-150 will be the debut vehicle for SK’s new “Nickel 9” NCM chemistry—incorporating cathodes that are nearly 90% nickel, along with just 5% cobalt and 5% manganese. It’s the first time such a battery, also called “nine-half-half,” has been commercialized, according to SK, and it means a higher energy density, longer range, and a makeup that’s better for the environment.

These cells are different than those to be made by the GM-LG joint venture, Ultium Cells LLC, as those follow a NCMA chemistry, also with 90% nickel but with the addition of aluminum.

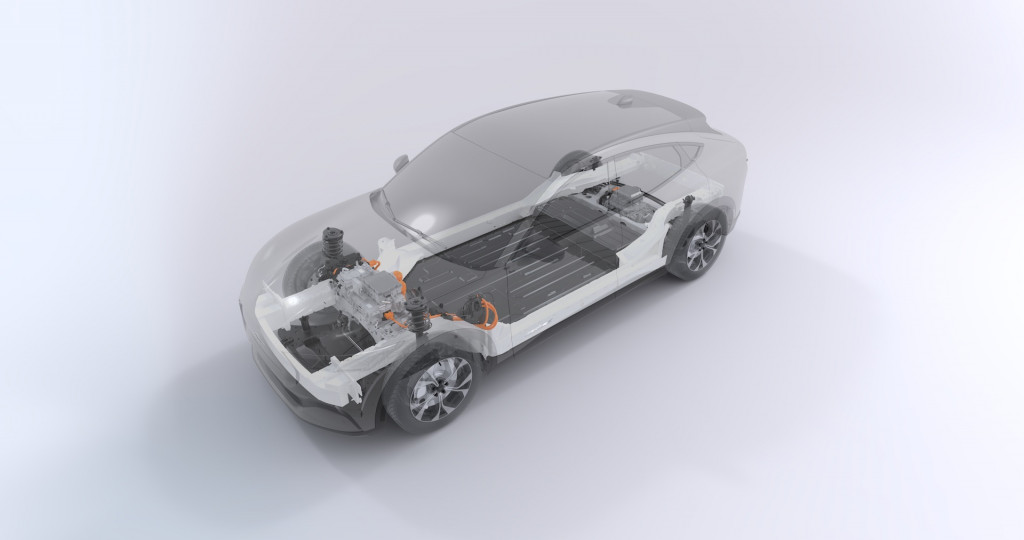

2021 Ford Mustang Mach-E electric powertrain

Ford, which currently uses LG as a supplier for the cells in its Mustang Mach-E electric car—sourced from Poland—notes that it’s working with “a number of battery suppliers to secure capacity and scale delivery for next-generation Ford and Lincoln battery electric vehicles.”

Ford chief operating officer Lisa Drake called SKI “an important partner in helping deliver batteries with better range and value for our fully electric vehicles by mid-decade.”

Ford said that it expects its global annual energy demand for EVs in 2030 to be up to 140 gwh in the U.S. and to 240 gwh globally. The company notes that the latter number is roughly 10 cell production plants of capacity.

SK innovation cells

“Our JV with Ford will play a pivotal role in fleshing out the electric vehicle value chain in the United States, a key objective of the current U.S. administration,” said SK Innovation CEO and president Kim Jun.

The announcement is a next step beyond what Ford announced last month—that it plans to build and vertically integrate cells for future electric vehicles, supported by a global battery “center of excellence” in Michigan it’s calling Ford Ion Park.

Ford also earlier this month announced an investment in the solid-state cell technology company Solid Power, becoming an equity owner alongside BMW.

Solid Power solid-state battery cells

Ford global development chief Hau Thai-Tang said in a call Thursday morning that although it still has a lot to do to “prove out the tech,” the flexibility to potentially produce solid-state cells on about 70% of the equipment that would be used in this joint venture is a potential upside.

“The flexibility to transition to a new technology is at the forefront of our considerations and our discussions with SK,” said Thai-Tang.

From here, the companies are in talks over a MOU for the new joint venture, and there are many details yet to finalize. It’s not yet certain whether SK’s Georgia facility will be part of those plans or whether the BlueOvalSK plants would be elsewhere.

Thai-Tang said that in the talks for the joint venture, it’s the likely plan for the mid-decade capacity to come from two fully utilized plants in North America.

Ford says that the relationship between the companies began in 2013, and SK Innovation noted help from Ford as well as the South Korean and U.S. governments in helping find a resolution in a recent trade dispute—one that, given a different outcome, might have left Ford scrambling for a solution.