General Motors sees a future of 600-mile EVs, enabled by advances that will double energy density, while it also targets a 60% cost reduction by mid-decade.

On Tuesday GM announced another step it sees as essential for making that happen: an “innovation center” for battery technology, with the aim of accelerating development and lowering costs for longer-range EV batteries.

GM didn’t disclose a value of the project, but it says that the facility builds on more than $5 billion that it’s already invested in batteries in the U.S. In a release GM’s VP for global product development, Doug Parks, called it “a key part of our plan to build cells that will be the basis of more affordable EVs with longer range in the future.”

In the new facility, called the Wallace Battery Cell Innovation Center and named after former GM director of battery systems and electrification Bill Wallace, who died in 2018, GM says that it will experiment with lithium-metal—which it sees as a next step for more range and lower cost—pure silicon, and solid-state battery technologies, as well as different cell form factors.

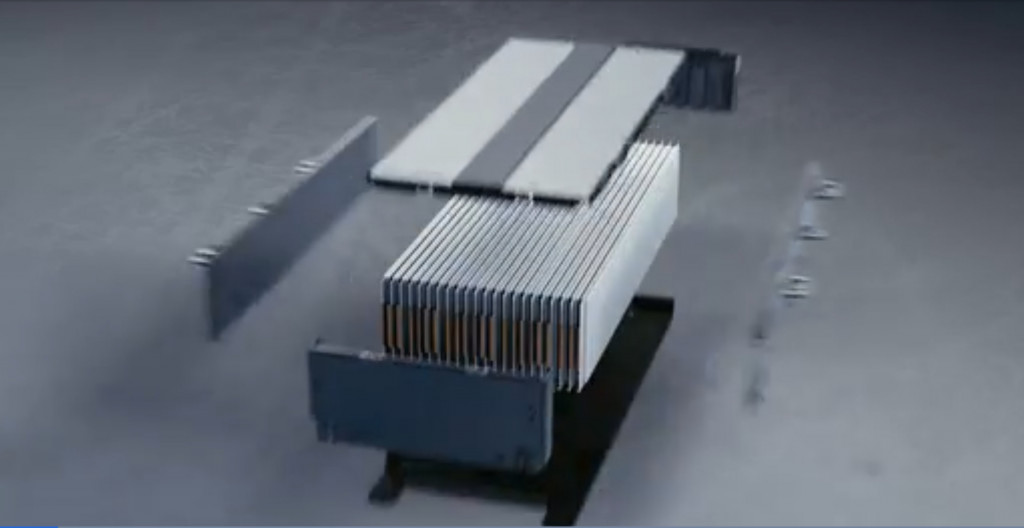

General Motors prototype lithium-metal battery cell

The flexible 300,000-square-foot facility will be part of GM’s Warren campus, next to its research and development center. It will operate in addition to GM’s Estes Lab, for battery durability, and the R&D site that already operates as the lead for battery development.

Specifically, the automaker says that it will be equipped to work with cells “based on GM’s proprietary formula” and as large as 1,000 mm, which is more than twice the width of GM’s large-format pouch cells due for installation in its Ultium EVs such as the GMC Hummer EV and Cadillac Lyriq.

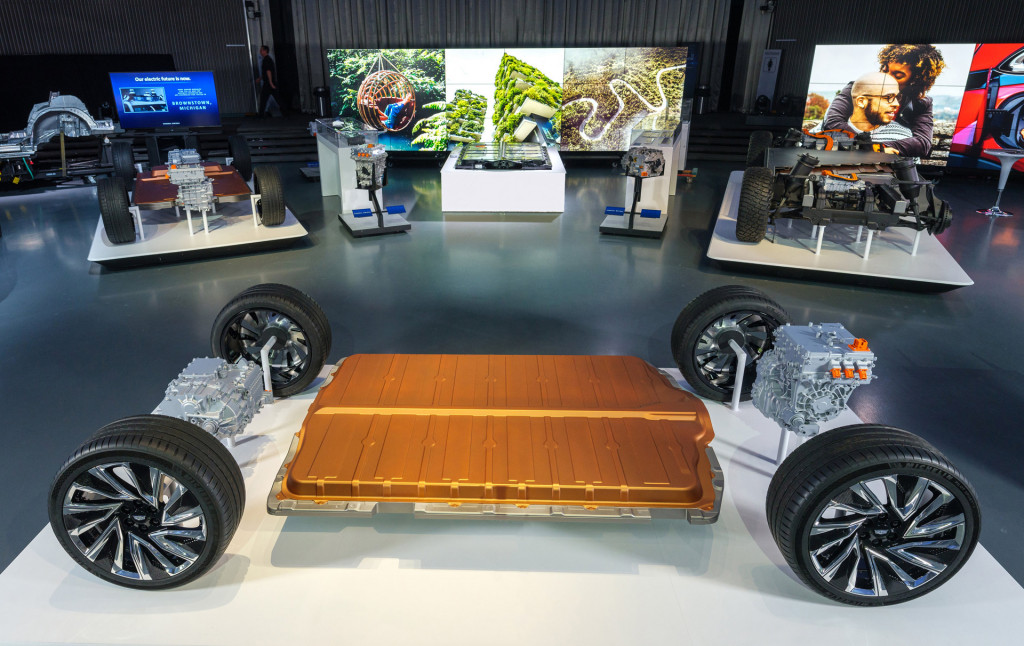

General Motors' BEV3 platform and Ultium batteries

The facility aims to accelerate technologies that could be deployed at the Ultium Cells LLC plants that are part of a joint venture between GM and LG Energy Solution. That includes Lordstown, Ohio, and Spring Hill, Tennessee, as well as two more locations yet to be announced.

But GM emphasized that this is a testing ground to be used with any of the automaker’s partners. “Whether it be Solid Energy, LG, or some of our other technology partners in electrolyte development, we’ll have it set up so that we can all benefit and collaborate together in the Innovation Center,” said Tim Grewe, in a background call before the announcement.

GM Ultium battery

The energy density under study at the facility will range from 600 to 1,200 watt-hours per liter, according to Grewe.

Ken Morris, GM’s VP for autonomous and EV programs, mentioned the company’s accelerated Ultium vehicle development—with the Hummer EV developed in just two years—and hinted that this facility might do the same for cell development.

“I think we have to be just as aggressive with cell chemistries, and how we manufacture the cells because those breakthroughs can come quickly,” said Morris. “We’re going to work with as many people as we can to make this happen quickly.”

GM’s Wallace Battery Cell Engineering Center (rendering)

The Wallace Center will include cell test chambers, cell formation chambers, a coating room, an electrolyte production lab, and material analysis equipment, among other equipment. It will also include a “data farm” to tie together all of the company’s findings.

It isn't intended to be a cell manufacturing facility, but it will be flexible enough to run a pilot line of cells with the same quality controls at the other plants, assured Grewe.

The facility is being built now and will be complete in mid-2022, GM says, with it potentially making prototype cells by the fourth quarter of 2022. It’s being designed for expansion to up to three times the initial footprint.