When Porsche developed its Taycan electric car on 800-volt systems, it had to go the expensive route—designing from scratch many components that EV makers might otherwise secure from suppliers.

That’s because while a robust supply network exists by now for 400-volt systems, the idea that 800V might be the future is just starting to be taken seriously.

Last week Hitachi announced the release of a new “high output” electric vehicle inverter that runs at 800V. It includes its own remarkably small high-output power module, which has double-sided direct water cooling.

While 800V systems allow engineers to cut weight by reducing the diameter of copper wire, they require redesigned connectors.

Hitachi 800V inverter and power unit

Hitachi notes that the 800V inverter has 2.7 times the power density of its present 400V inverter tech, and says that the 800V inverter “contributes to both comfortable acceleration performance of the vehicle and faster charging times.”

The Hitachi unit isn’t quite the first, though. Last month, Delphi Technologies announced that it would be the first major auto-industry supplier to make an 800-volt inverter. Delphi claimed that it had already secured a $2.7 billion supply deal for volume production over eight years, with “a premier global OEM” in “a high-performance vehicle” starting in 2022.

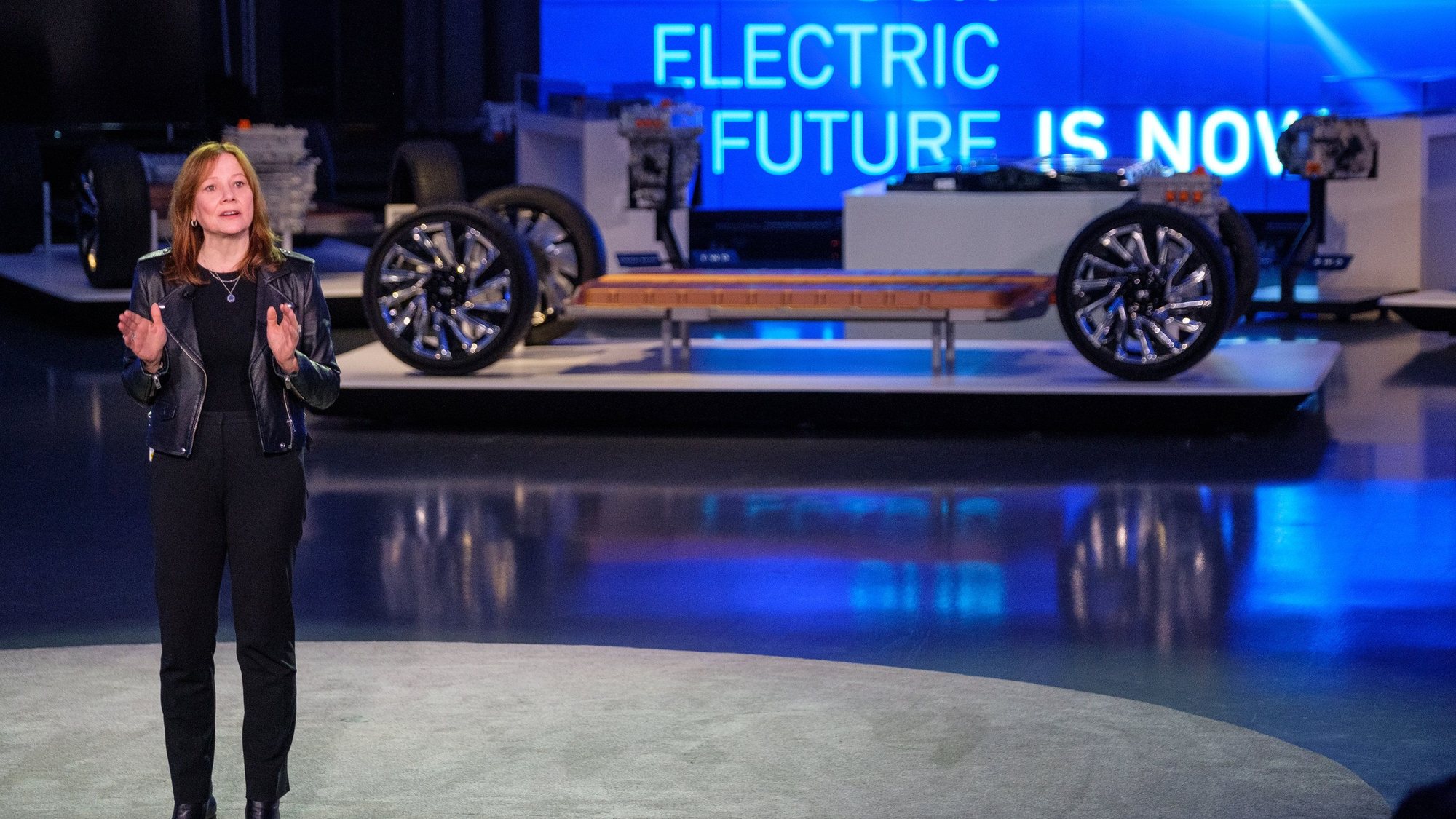

Volkswagen Group PPE modular EV platform

Because of the higher price point, 800V tech is expected to trickle down from the luxury and performance market on down, eventually, to more affordable vehicles. Hyundai and Kia are working on 800V systems, potentially for multiple upcoming Genesis vehicles. The Volkswagen Group’s premium electric platform, called PPE, will be 800V. And it’s likely (though certainly not confirmed) that GM’s BEV3 architecture, which is aiming for maximum usability across types of vehicles, will have an option baked in for 800V.