Lucid Motors calls its motor design miniaturized, and it’s long boasted that the light and “impossibly compact” motor in its Air electric sedan is lean enough to fit into an airplane carry-on.

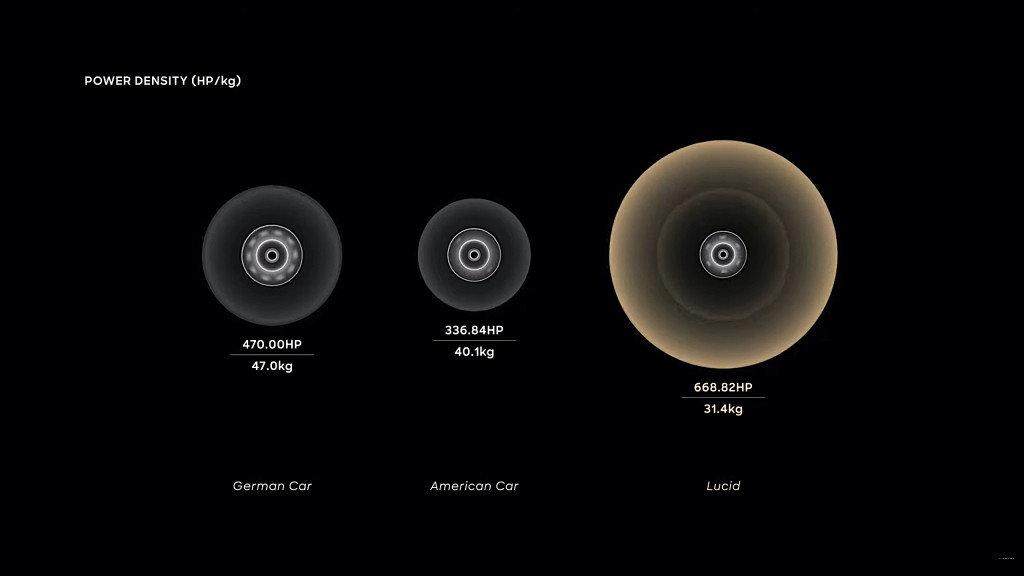

Lean and small is only one aspect, however. Lucid’s motors weigh just 67 pounds each and are capable of generating 670 hp—yes, that’s 10 hp per pound.

2022 Lucid Air

Further, Lucid’s silicon carbide inverter, reduction gearset, and differential, packaged together, weigh about 163 pounds.

It is very, very power-dense. And in a tech talk released by the company on Tuesday, Lucid CEO and CTO Peter Rawlinson and Powertrain VP Emad Dlala ran through the priorities the motors were designed around, and how power and efficiency, through low resistance and thermal management, have been part of the plan from the start—along with ease of manufacturing.

You’ll want to watch the entire presentation—more than an hour—for the physics lesson within, and you’re bound to learn a lot not just about this unit but motors in general. But these four slides, comparing Lucid's motor to motors from Tesla and Porsche, get to the gist of it.

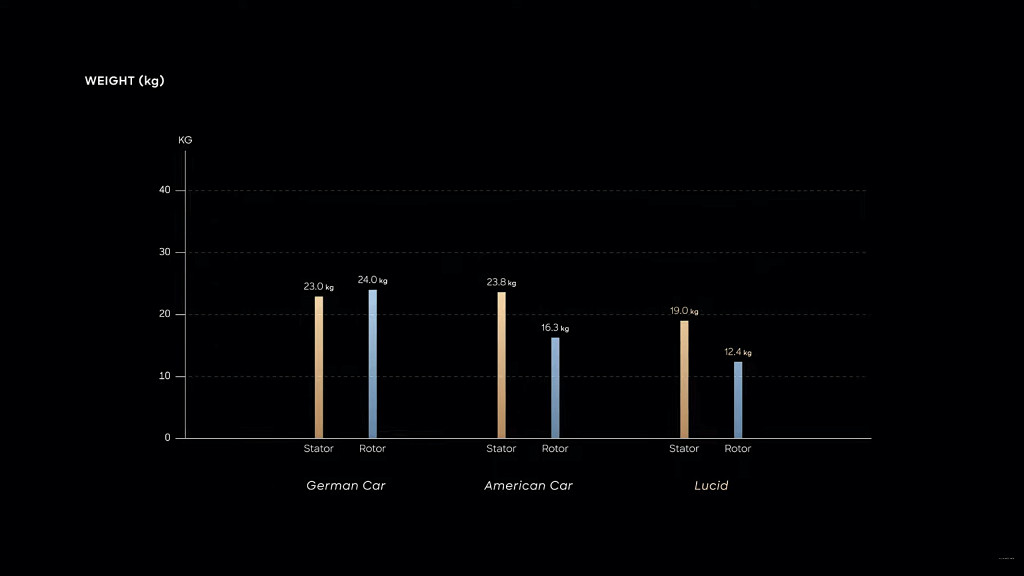

Lucid weight of stator and rotor compared

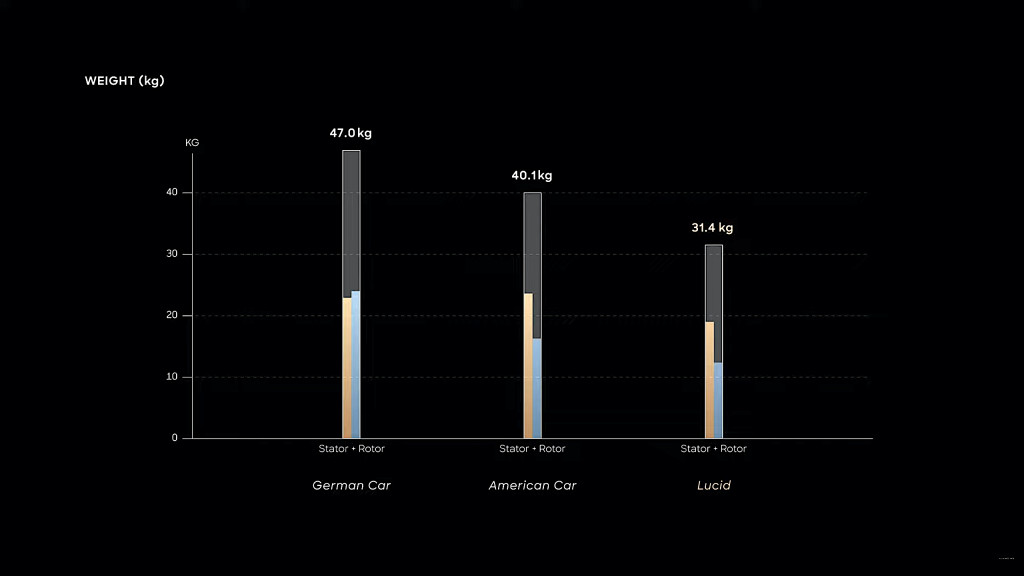

Lucid motor weight compared

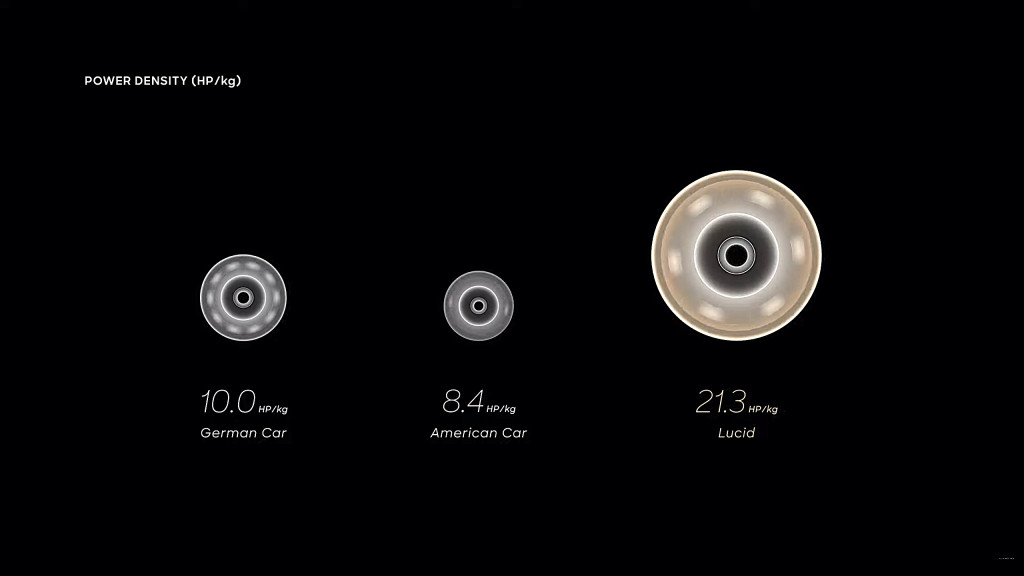

Lucid power density compared

Lucid power and motor weight compared

Rawlinson notes that the project included going back to the physics and looking at the whole powertrain as a single holistic inertial system.

The two spend much time discussing the design of the stator—the static outer portion of the motor that, with the current shaped by the inverter, creates the magnetic field that rotates the rotor in the middle.

For instance, the stator for Lucid’s six-pole permanent-magnet synchronous motor doesn’t use copper-wire windings like many such motors, and it doesn’t use hairpins either. Instead, for lower power losses plus ease of assembly, Lucid looks to a continuous-winding assembly that wraps into the stator with a limited number of welds. It’s made with a CNC-controlled machine and a process that resembles weaving. Then a CNC-controlled mandrel helps align and insert the woven mesh.

Carbon wrap on Tesla Model S Plaid motor

The pair even poke a little fun at the workaround that Tesla resorted to in its motors for the Plaid—a carbon-fiber shell that Rawlinson notes is the same sort of technology used in hydrogen storage for fuel cells, to hold tremendous pressure in. To scale that to high volume is going to be very expensive, Dlala speculates.

Lucid also cools its motor differently than Tesla, Porsche, or any other designs we’re aware of. Lucid’s strategy extracts whatever heat it can super-close to the slots rather waiting until the heat reaches outward. A middle channel in the stator functions as a manifold, running ATF (automatic transmission fluid) through narrow channels, helping extract heat through that mesh.

The busbars connecting the motor to the inverter are also the shortest possible, to reduce resistance (and thus heat). It’s an advantage of the motor as it was designed in a single unit with the inverter.

Lucid's Rawlinson and Dlala presenting drive unit

Bottom line: Lucid emphasizes that its drive units are light, compact, efficient, power-dense, and can be scaled up.

Although Lucid doesn’t actually lay out an efficiency analysis of the motor unit versus the unit from the Taycan and Model S Plaid, it implies based on the whole presentation that its motors also make a huge contribution to efficiency.

To that point, Rawlinson ventures that the motor itself weighs so little—just 11% of the overall battery-pack mass—that if they can achieve that gain in efficiency from the unit’s design it is essentially a “zero mass drive unit.”

That may be the point to help enable an advantage for Lucid in the future, as it produces EVs that go farther with smaller battery packs and, perhaps, a scaled-down version of this unit.