If it's built out to the full size in the original plans, the Tesla gigafactory outside Reno, Nevada, will cover 10 million square feet.

That's the equivalent of more than 260 U.S. football fields, which would make it one of the largest buildings in the world.

Yesterday, Tesla Motors CEO Elon Musk officially opened the gigafactory building, which today is 14 percent of that size on a 3,000-acre site.

DON'T MISS: Tesla Model 3: video of first ride in prototype $35k electric car

Owners of Tesla electric cars have been invited to an event to be held at the plant on Friday, but Musk spoke to the press yesterday from the site and declared it officially open.

The factory's main mission is to produce lithium-ion cells at a far lower cost than any today, which will make the battery cost of the company's upcoming Model 3 sedan low enough for a starting price of $35,000.

The Tesla Model 3 is supposed to go into production just 12 to 18 months from now, and ensuring the supply of cells and battery packs in sufficient volumes is what made the huge building necessary in the first place.

![Tesla Motors gigafactory - size comparisons [source: EV Obsession] Tesla Motors gigafactory - size comparisons [source: EV Obsession]](https://images.hgmsites.net/lrg/tesla-motors-gigafactory--size-comparisons-source-ev-obsession_100496313_l.jpg)

Tesla Motors gigafactory - size comparisons [source: EV Obsession]

The ultimate cost of the site could be as high as $5 billion, though Panasonic—which will fabricate the cells—and other partners are expected to contribute part of that cost.

The Associated Press notes that Panasonic's share of the total will be $1.6 billion. The company expects to begin production of cells before the end of this year.

Tesla moved up its plans for high-volume production of the Model 3 after it received more than 350,000 deposits of $1,000 each for the car in late March and early April.

CHECK OUT: Panasonic to build cells at Tesla gigafactory this year: report

The company's ability to get the Model 3 into volume production remains one of its greatest challenges.

The launch of its previous product, the Model X electric luxury crossover utility, was plagued with delays and glitches, many of them due to its innovative but hard-to-engineer "falcon doors."

Musk said earlier this year that Tesla plans to have sold half a million Model 3 cars a year by the end of 2018.

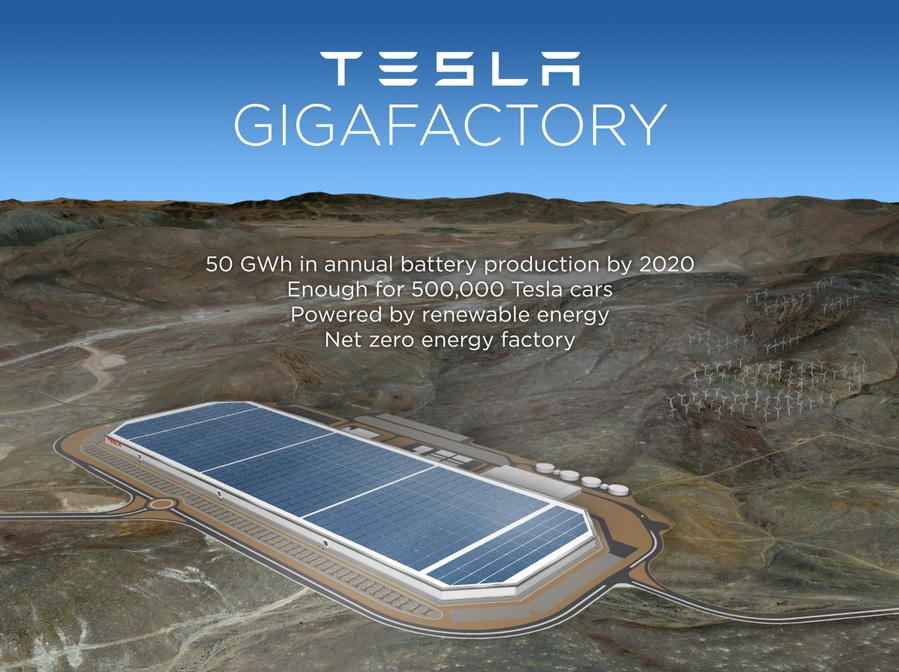

Rendering of Tesla battery gigafactory outside Reno, Nevada, Sep 2014

Both industry analysts and competitors remain skeptical that it will be able to reach that volume in anything like the proposed timeframe.

Meanwhile, work on the gigafactory has proceeded over the last two years and is currently at a fever pitch, as The Wall Street Journal notes.

One thousand workers on two shifts are finishing the cell fabrication space, installing the climate humidity controls required to produce the electrode material within sterile compartments, and moving in equipment.

A 1.9-million-square-foot building is already assembling home energy-storage batteries for Tesla's separate Powerwall product line, using Panasonic cells imported from Japan.

By 2020, Musk projects, the factory could be producing as much as 105 gigawatt-hours of lithium-ion cells.

Tesla Model 3 design prototype - reveal event - March 2016

That's 105 million kilowatt-hours, or enough for more than 1 million of the 90-kwh battery packs in the highest-capacity Tesla Model S and Model X.

Tesla hasn't released battery capacities for the Model 3 yet, and it also notes that up to one-third of the gigafactory's output is anticipated to go to its energy-storage products.

The full cost reductions from producing lithium-ion cells domestically, however, will require setting up entire supply chains for lithium and other necessary components.

Analysts don't expect that to have been created by the time cell production starts in volume next year, meaning that the batteries built there could cost more than planned.

Still, if it reaches its goal of 100 gwh or more of annual production, the gigafactory's annual output would be 10 times the total lithium-ion cell production globally today.

Tesla Model 3 spotted at service center

Speaking to the media at yesterday's opening, Musk said that the Model 3 could generate $5 billion a year in profit once volume of 500,000 cars a year is reached.

That money would allow Tesla to proceed with elements of the second part of its master plan, including an electric semi truck.

The company will need a "small" additional capital raise to get there, Musk said.

Tesla Motors has lost money throughout its 12-year history, and has not had a profitable year to date.

_______________________________________