There are many routes to improving fuel efficiency in modern cars, but one route in particular seems to be resonating with automakers, automotive engineers and designers: Shedding weight.

A survey of 900 automotive engineers and designers conducted by Wards Auto and sponsored by DuPont showed that lightweight materials and weight reduction were a primary focus for hitting future economy and emissions targets.

Behind that, 39 percent also said their company was looking into improving the efficiency of conventional powertrains, and over a quarter are now looking into electrification.

The latter figure covers all forms of electrification, including hybrids and plug-in hybrids as well as all-electric drivetrains. Hybrids are receiving the most attention and resources, at 54 percent of electrified powertrains.

It doesn't include fuel-cell vehicles though, which just a tenth of those surveyed said was in development. Slightly more in focus, at 11 percent, is downsizing, while 13 percent of engineers and designers are looking towards diesel.

MORE: Hybrids, Electrics Not Needed To Reach 54.5 MPG In 2025: Industry Exec

Transmission improvements, low rolling resistance tires and autonomous driving systems, among others, were mentioned by 15 percent of respondents.

The auto industry's focus on lighter weight though is clear even from looking at the last generation or two of dozens of popular vehicles on the market.

While some outliers have put on weight for various reasons--including size gains or bigger equipment and safety tallies--a number of high-profile models have gone on substantial diets.

Biggest of all is Ford's 2015 F-150 pickup, which has shed as much as 700 pounds in some versions thanks to a new all-aluminum body and chassis.

Also aluminum and also a great deal lighter than its predecessor is the current Land Rover Range Rover, which has lost 400 lbs. BMW has looked to carbon-fiber reinforced plastic to keep the weight of its i3 and i8 plug-ins low--the latter undercuts BMW's 6-Series coupe despite the extra weight of batteries and electric motors. Some automakers still consider CFRP to be too expensive for widespread use.

At the lower end of the market, the new Volkswagen Golf is lighter than its predecessor through considered use of high-strength and lightweight steel alone.

Of light-weight construction methods, aluminum was cited as the most significant material for reducing weight. 27 percent of those surveyed said they relied on aluminum most heavily, with magnesium, high-strength steel and special plastics also ranking highly.

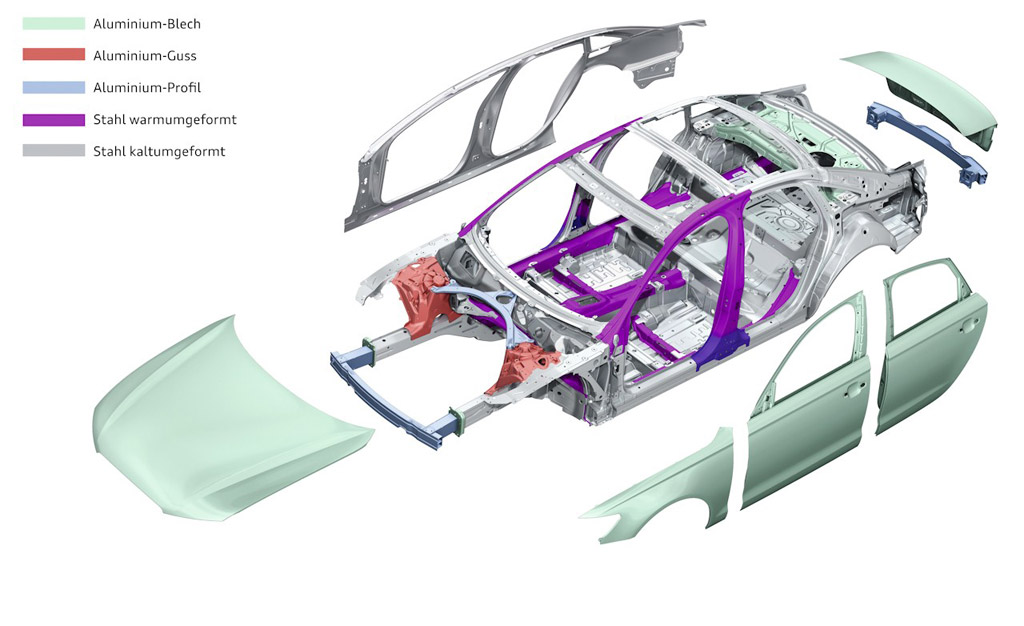

2012 Audi A6 aluminum and steel construction

Light weight more important than ever

Most significant is that the latest survey marks a change from a similar survey in 2011, in which lighter weight ranked third.

High-profile light-weight cars are a factor in this, as is the realization that reducing the weight of a vehicle has a knock-on effect--you can reduce the weight of components too, as they no longer need to support such a heavy vehicle. In turn, further parts can be simplified and reduced.

The change has also happened as the pace of powertrain developments is unlikely to continue at the rate it has been doing.

At the moment, the industry is well on target for meeting gas mileage goals. But once the low-hanging fruit of gas mileage, finding further gains from the humble combustion engine will become ever more difficult, particularly as the CAFE 54.5 mpg regulations for 2025 draw ever closer.

The best way to improve the fuel efficiency of vehicles is of course to employ several different techniques--and as the survey's percentages show, engineers are working on that, and were permitted multiple choices on some questions.

But if there's one thing we'll definitely see over the next few years, it's lighter vehicles. That isn't just good for economy, but ride, handling and running costs too.

_________________________________________