It's interesting to see the variations among green technologies as automakers, both in production cars and motorsports, strive for greater fuel efficiency and reduced emissions. The most common means for automakers to boost gas mileage thus far have been hybrid-electric technology and turbodiesel engines.

However, we've also seen such lightweight materials as carbon fiber and aluminum used in production cars, and now we have another technology that’s starting to make waves in the industry: the flywheel-based Kinetic Energy Recovery System, or KERS.

Probably most widely recognized from its implementation in the world of Formula 1, as well as this Porsche 911 hybrid race car, kinetic systems that use a spinning flywheel to capture and store energy are nothing new. In fact, they've been tested by automakers (including Volvo) for decades.

But toughening fuel consumption and emissions regulations being implemented around the globe have turned the spotlight back onto KERS technology. Once again, Volvo is investigating the potential of flywheel-based hybrid systems.

The Swedish automaker plans to start testing a prototype vehicle equipped with a flywheel KERS on its rear axle this fall, with the goal of having such a system available for production within the next few years.

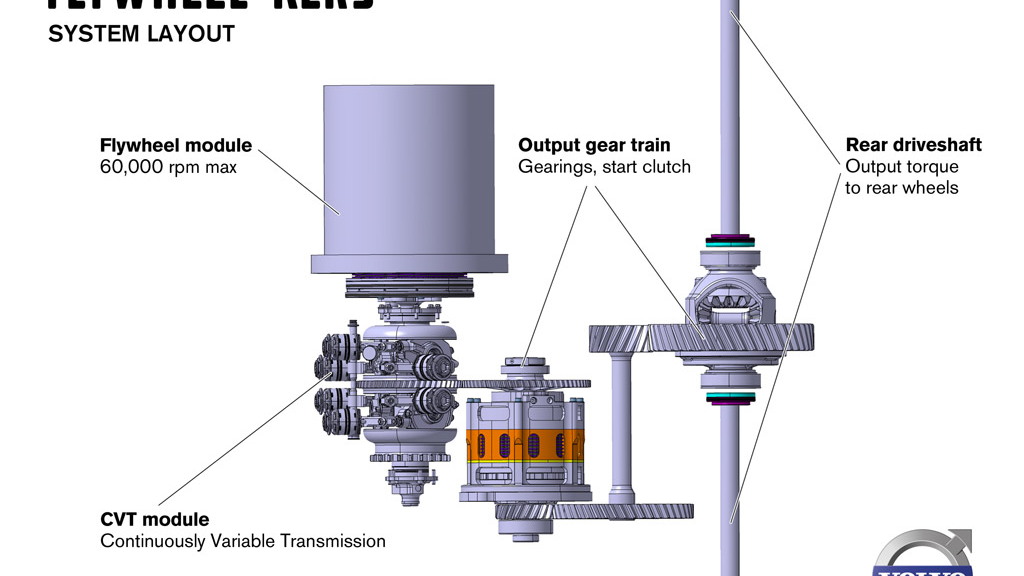

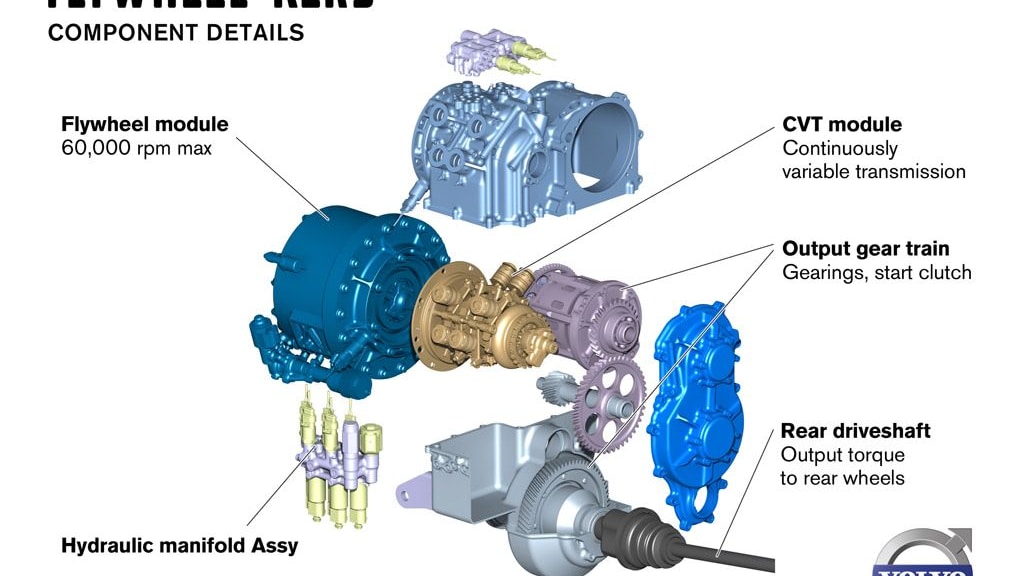

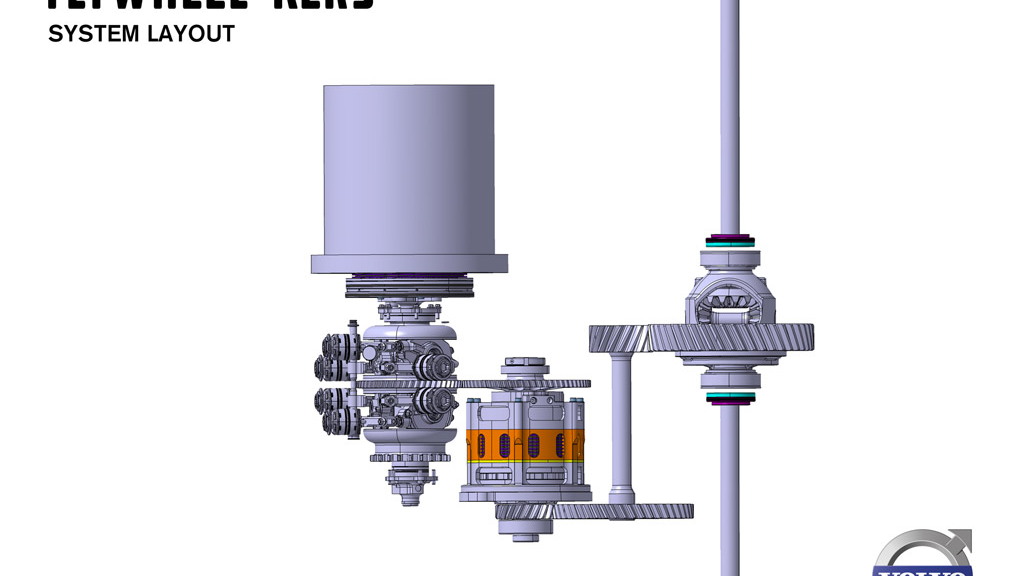

Basically, when the brakes are applied, the brake energy is recovered by spinning the flywheel, which can reach speeds of up to 60,000 rpm. This energy can then be transferred to the rear wheels via a specially designed transmission.

According to Volvo, enough energy can be stored in the wheel when the car comes to a complete stop to accelerate it again when the driver presses the accelerator. In this fashion, the engine that powers the front wheels can be turned off whenever the car comes to a stop at a traffic light or intersection.

In initial testing, Volvo says the flywheel can add an additional 80 horsepower burst of energy when needed, and can provide a fuel economy gain of up to 20 percent.

Of course, since the flywheel is activated by braking and the duration of the energy storage--i.e. the length of time the flywheel freely spins--is limited, the technology is at its most effective during stop-and-go driving in the city.

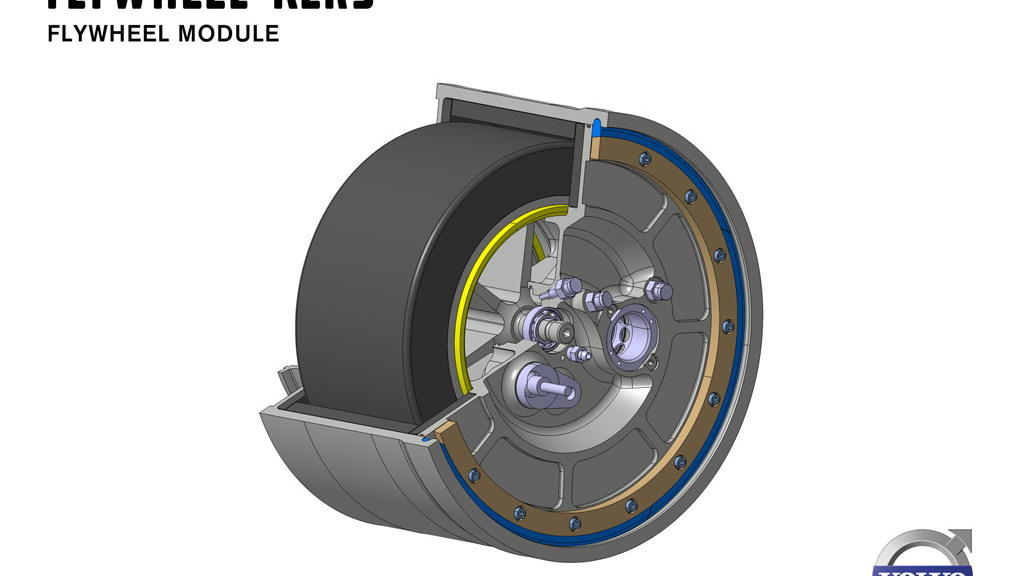

KERS technology is also relatively cheap compared to regular hybrid systems, which require expensive battery packs, electric motor-generators, and electronic control modules. It's also quite light, as the flywheel is constructed from carbon fiber and weighs just 13.2 pounds. It also spins in a vacuum to minimize frictional losses.

This is hardly Volvo's only attempt at advanced gas-saving technologies, though. It is now testing several hundred all-electric Volvo C30 Electric conversions, and it just offered its experiment Volvo V60 Plug-In Hybrid wagon to journalists for test drives.

The more the merrier, we say.

[Volvo via MotorAuthority]

+++++++++++