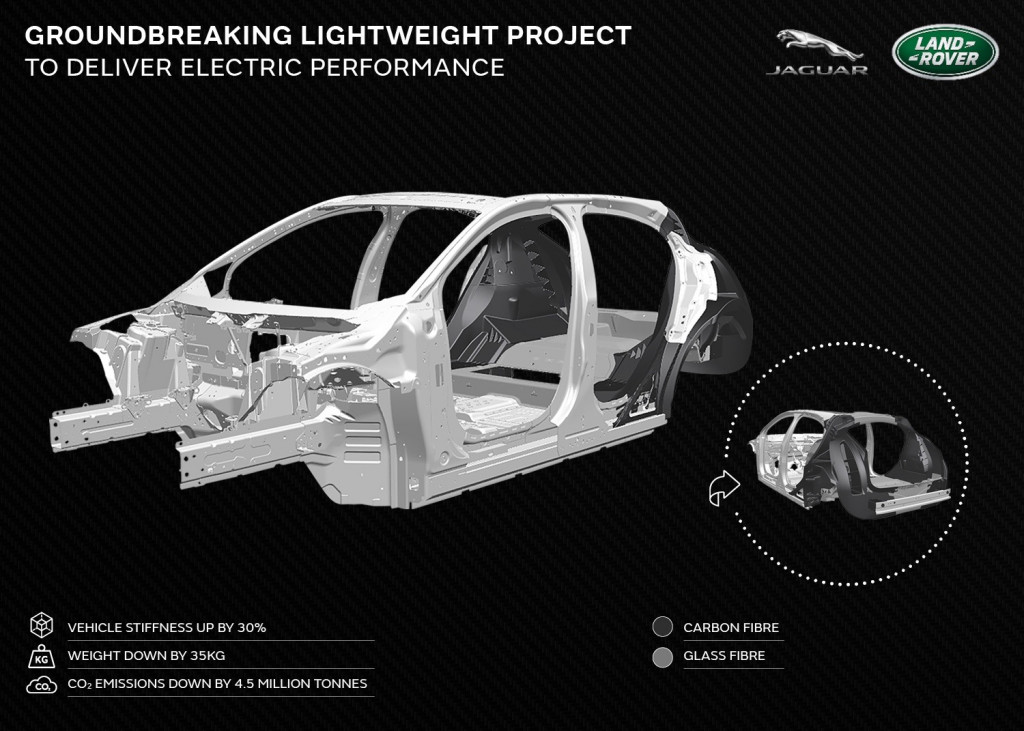

Jaguar Land Rover (JLR) hopes improve the efficiency of its future electric vehicles through increased use of lightweight composite materials.

The automaker is leading an industrial consortium in the Tucana Project, a four-year program that aims to accelerate the implementation of electric powertrains and lightweight materials in the United Kingdom auto industry.

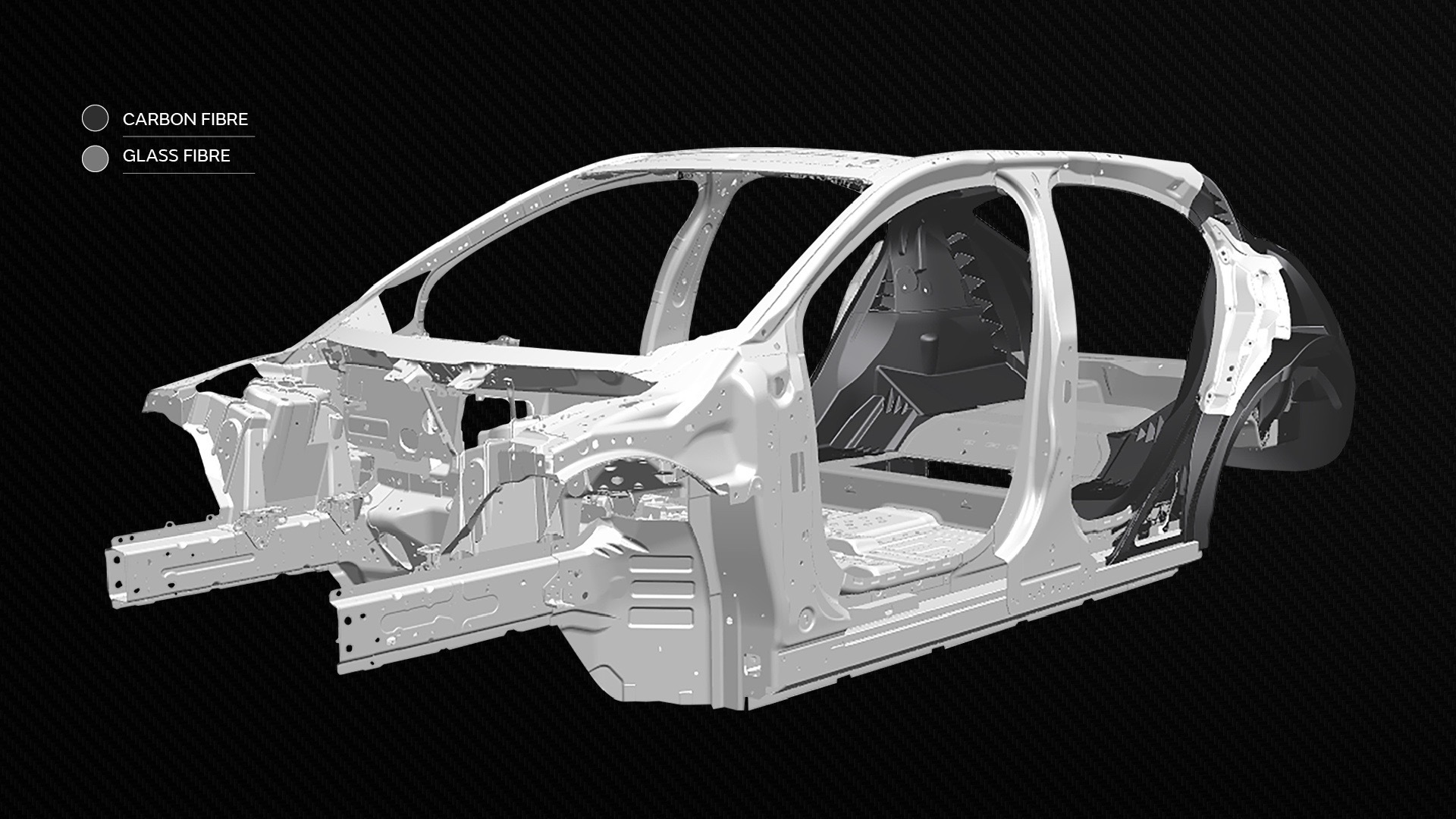

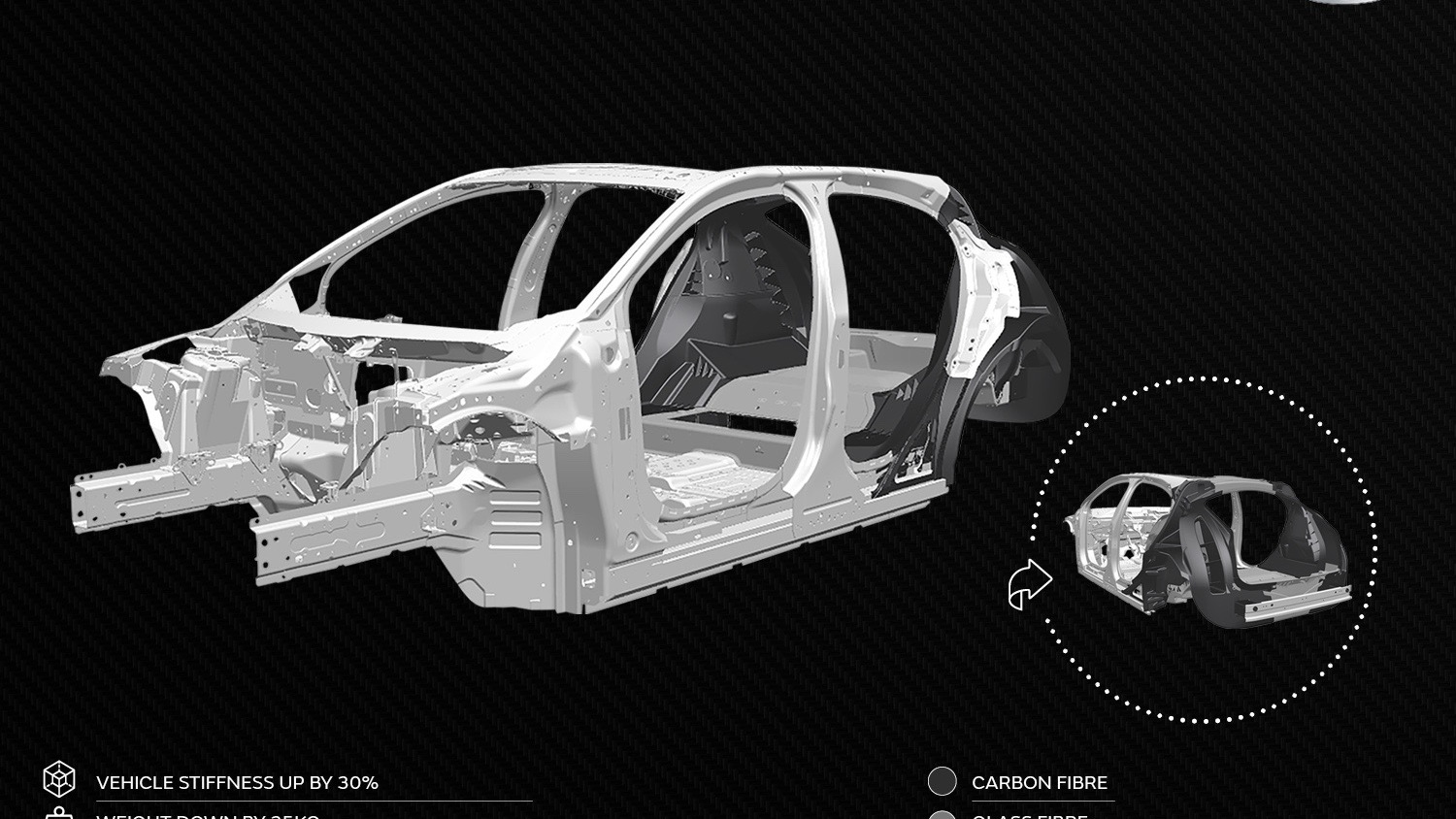

Research undertaken as part of the Tucana Project will lead to the development of lighter vehicle structures that use materials like carbon fiber in place of the steel and aluminum used in today's JLR vehicles, the automaker said in a press release Tuesday.

Goals for the project include increasing structural stiffness by 30%, and reducing the weight of the basic vehicle structure by 77 pounds, JLR said. The automaker expects to have a fleet of test vehicles ready by 2022.

Reducing weight improves nearly every aspect of a vehicle—from acceleration to efficiency. When it comes to electric cars, a lighter body shell also allows for a larger battery pack, and thus increased range, JLR said.

Jaguar Land Rover Tucana Project

Automakers have been focusing on weight reduction both to meet stricter efficiency standards and to counteract the accumulation of safety and convenience features in modern cars. But it's usually not as easy as simply substituting one material for another.

Carbon fiber generally means a more intensive manufacturing process, but one that pays off in weight savings, and in terms of lower lifetime emissions.

Automakers have considered using it for everything from bodies to interiors and even wheels, but it's caught on more slowly than anticipated. It's still mostly used in low-volume applications, primarily in performance vehicles.

While companies continue looking for ways to scale up carbon-fiber production, various projects hope to make carbon fiber from plants with less carbon impact—possibly even close to carbon-neutral.

One project in Sweden even aims to use carbon-fiber vehicle body panels as "mass-less" batteries. That would dramatically reduce weight by eliminating the need for a separate—and very heavy—battery pack, but is still only in the research stage.